Steam Methane Reformer tubes inspectionv

Industrial context

Steam Methane Reforming (SMR) tubes are high-alloy, catalyst-filled components housed within reformer furnaces, where they facilitate the conversion of natural gas and steam into hydrogen and carbon oxides (syngas). These vertically mounted tubes operate under extreme temperature and pressure, making them critical to hydrogen production for industries such as refining, fertilizer manufacturing, and food processing.

Due to tube’s internal pressure and operating temperature the material is subject to permanent deformation with time up to rupture: creep mechanism. Creep start as micro cavities, they eventually coalesce to form grain boundary cracks which, in turn interlink to form multiple boundary length cracks which subsequently propagate to cause failure.

Early detection of creep damage and/or defects is essential for monitoring damage evolution and, in particular, to make accurate assessment of fitness for service and /or remaining lifetime.

Surface inspection methods such as Eddy Current Testing (ECT) can detect defects (e.g., cracks, cavities) only if they are located near the outer surface of the tube. However, ECT cannot detect defects within the full thickness of a tube (10 to 15 mm). When damage is detected by ECT, it typically means that the tube is nearing the end of its service life.

The columnar grain structure scatters ultrasonic waves more than the equiaxed structure does. Therefore, variations in the ratio of equiaxed to columnar grains (typically 1:3) result in signal attenuation, even in unused tubes, which complicates the measurement of the backwall echo.

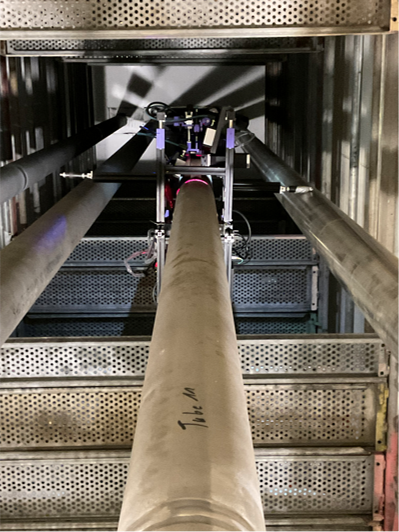

Accessibility can be challenging with long tubes (12 meters), weld caps, and limited space between tubes, often requiring the use of a complex crawler for inspection.

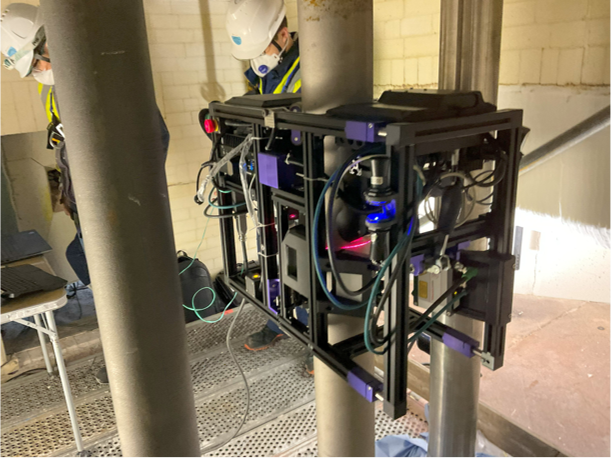

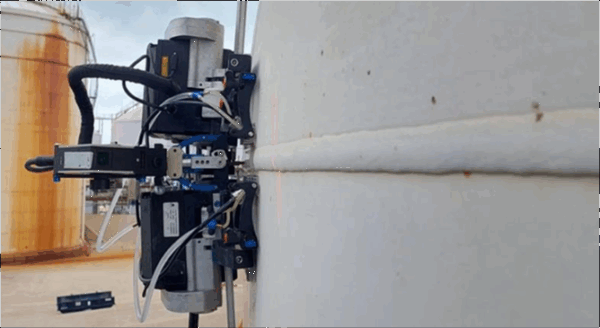

EKOSCAN has developped a specialized scanner designed to meet the toughest challenges of Steam Methane Reformer (SMR) tube inspection. The system combines laser profilometry and 3D reconstruction to capture precise surface geometry, with an integrated PAUT platform capable of measuring variations in attenuation and velocity to assess creep damage, as well as providing accurate thickness measurements.

Engineered for full coverage, the scanner can travel up to 12 meters inside the tube and maneuver between adjacent tubes, ensuring access to areas that are traditionally difficult or impossible to inspect.

By integrating advanced imaging, ultrasonic diagnostic methods, and automated scanning technologies, the solution enables a comprehensive assessment of tube condition, facilitates earlier identification of creep-related degradation, supports life extension strategies, and reduces the risk of unplanned outages.

Sources

- Phased-array ultrasonic testing for thickness measurement in industrial applications

Jian, X., Li, T., Drinkwater, B. W., NDT & E International, vol. 46, pp. 120–128, 2012,

DOI: 10.1016/j.ndteint.2011.11.008 - Precision thickness gauging using phased-array probes: Challenges and solutions

Ghoshal, G., Rose, J. L., Ultrasonics, vol. 54, no. 3, pp. 715–723, 2014,

DOI: 10.1016/j.ultras.2013.10.012 - Laser triangulation for high-precision ovality measurement of cylindrical components

Petrov, I., Cheng, K., Precision Engineering, vol. 38, no. 1, pp. 34–42, 2014,

DOI: 10.1016/j.precisioneng.2013.07.003 - Comparison of phased-array UT and laser profilometry for corrosion mapping in pipelines

Bray, D. E., Stanley, R. K., Materials Evaluation, vol. 75, no. 5, pp. 582–590, 2017,

DOI: 10.1007/s11990-017-0123-4 - Advanced phased-array techniques for corrosion and erosion thickness mapping

Ahlberg, T., Sandgren, C., Insight – Non-Destructive Testing and Condition Monitoring, vol. 59, no. 3, pp. 132–139, 2017,

DOI: 10.1784/insi.2017.59.3.132 - Laser-based 3D scanning for ovality and deformation analysis in pressure vessels

Kumar, J., Krishna, M. G., Journal of Pressure Vessel Technology, vol. 140, no. 4, pp. 041403, 2018,

DOI: 10.1115/1.4039210 - Integration of phased-array UT and laser metrology for comprehensive pipe inspection

Neau, G., Roy, O., Journal of Nondestructive Evaluation, vol. 38, no. 2, pp. 35, 2019,

DOI: 10.1007/s10921-019-0578-7

See our other case studies