Pressure vessels welds inspection

Industrial context

A pressure vessel is a sealed container designed to hold gases, liquids, or steam under pressure, typically operating above 15 psig (pounds per square inch gauge) and storing potentially explosive energy. Pressure vessels feature a wide range of welds, including circumferential, longitudinal, and nozzle welds.

Because these vessels operate under high pressure, any flaw in fabrication can result in catastrophic failure. As part of quality assurance, weld testing ensures that joints meet code requirements and provide safe, reliable service throughout the vessel’s life. This is both a regulatory and safety requirement, governed by industry standards such as ASME and API.

Pressure vessel thickness varies widely, from a few millimeters for small, low-pressure applications to significantly larger values, such as the 122 mm (4.8 in) shell thickness for the High-Temperature Engineering Test Reactor’s pressure vessel. It is thus necessary to have ultrasonic techniques that can accomodate this entire thickness range. Nozzle inspections present also a challenge due to accessibility issues, geometric challenges like varying curvature, particular weld profiles and potential interference from internal components.

Material wise, pressure vessels can be made out stainless steel and be cladded making ultrasonic inspection more complicated.

Angle-beam UT, PAUT, and TOFD remain the cornerstone ultrasonic techniques for the inspection of pressure vessel welds. They have long been recognized for their reliability in detecting flaws and ensuring compliance with industry codes. Building on this foundation, advanced full matrix capture and total focusing method techniques are increasingly adopted, particularly for critical applications and fitness-for-service evaluations where enhanced data quality and inspection confidence are essential.

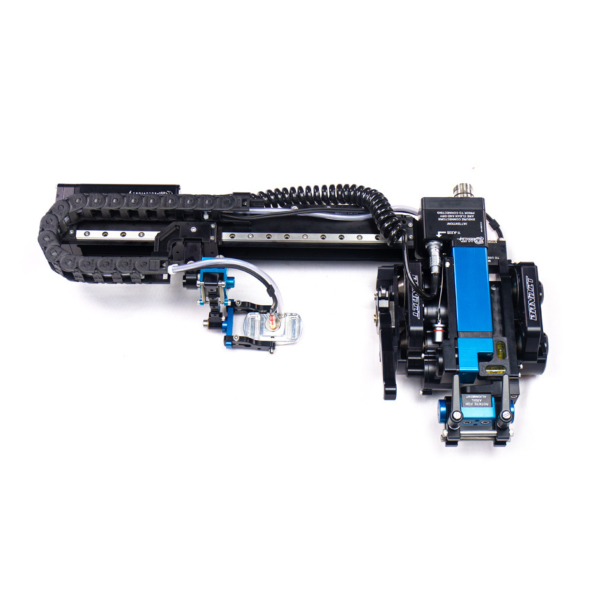

Semi-automated scanners for accessible welds and fully automated crawlers for large vessels or restricted areas guarantee accurate probe positioning, stable coupling, and complete weld coverage with minimal operator dependence. This ensures inspection repeatability, reduces variability between operators, and improves productivity even in complex field conditions. Inspection strategies can be further adapted with standard or custom-built PAUT and TOFD probes to provide optimal coverage across both carbon steel and stainless steel welds. Beyond these established approaches, next-generation methods such as pitch-catch TFM with PWI and PCI mixing, combined with mode fusion, deliver significant improvements in detection capability and characterization. These techniques provide higher resolution imaging, reduce interpretation uncertainty, and make data easier to analyze. As a result, inspectors benefit from clearer indications, faster evaluations, and greater confidence in their decisions.

EIG brings these advanced ultrasonic inspection technologies to the field through the SPIKE phased-array electronics platform, EK31 probes, and the VENOM scanner family. Together, these solutions enable high-performance weld inspection strategies that combine state-of-the-art imaging with practical deployment tools, supporting safer, more efficient, and more reliable pressure vessel operation.

EKOSCAN’s solution combines semi-automated or mechanized scanning, specialized PAUT/TOFD probes, and state-of-the-art phased array systems into a turnkey inspection package. This ensures reliable flaw detection, accurate defect sizing, and full compliance with pressure vessel codes, while improving productivity and reducing operator dependence.

Sources

- Total Focusing Method: Theory and applications

Roy, O., Holmes, C., Fink, M., Journal of Applied Physics, vol. 114, no. 5, pp. 054901, 2013,

DOI: 10.1063/1.4811197 - Plane Wave Imaging for ultrasonic NDT: Optimization of inspection parameters for welds

Neau, G., Reverdy, F., NDT & E International, vol. 98, pp. 12–22, 2018,

DOI: 10.1016/j.ndteint.2018.04.003 - Adaptive Plane Wave Imaging for complex geometries in ultrasonic testing

Voillaume, H., Raillon, R., Caleiro, C., IEEE Transactions on Ultrasonics, Ferroelectrics, and Frequency Control, vol. 67, no. 3, pp. 587–598, 2020,

DOI: 10.1109/TUFFC.2020.2971234 - Comparison of TFM and PWI for defect characterization in austenitic welds

Raillon, R., Voillaume, H., Research in Nondestructive Evaluation, vol. 30, no. 4, pp. 237–256, 2019,

DOI: 10.1080/09349847.2019.1631854 - Ultrafast ultrasonic imaging for NDT: Application to weld inspection with matrix arrays

Roué, D., Goursaud, S., AIP Conference Proceedings, vol. 1839, no. 1, pp. 020008, 2017,

DOI: 10.1063/1.4981210 - Plane Wave Imaging with limited-angle data: Application to weld inspection

Chassignole, B., Billebeau, B., Ultrasonics, vol. 113, pp. 106502, 2021,

DOI: 10.1016/j.ultras.2021.106502 - Advanced ultrasonic imaging techniques for NDT: From FMC to PWI and TFM

Benoist, P. (CEA LIST), IOP Conference Series: Materials Science and Engineering, vol. 188, no. 1, pp. 012012, 2016,

DOI: 10.1088/1757-899X/188/1/012012

See our other case studies