Tank corrosion mapping

Industrial context

Storage tanks are critical infrastructure used for storing liquids such as hydrocarbons, chemical, etc. Corrosion is one of the most significant degradation mechanisms affecting the integrity of tanks. It can occur due to external exposure (weather, soil moisture, atmospheric pollutants) or internal exposure (chemical stored, water content, bacteria, temperature). Left unchecked, corrosion can lead to leaks, environmental contamination, fire/explosion risks, costly downtime or catastrophic failure.

Ultrasonic corrosion mapping is a powerful technique for evaluating wall thickness loss due to corrosion, but it comes with several practical and technical challenges. Tanks are often large structures, and access may require scaffolding or rope access leading to productivity issues. Ultrasonic inspection requires coupling consistency to obtain repeatable results and deal with painted or line surfaces. Remote access ultrasonic testing crawler offers a solution to accessibility issues but require tether management (weight of the umbilical, signal attenuation with length electromagnetic noise…)

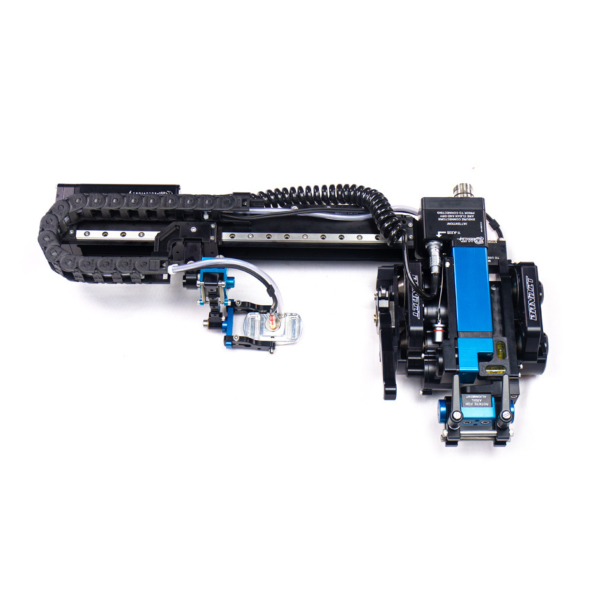

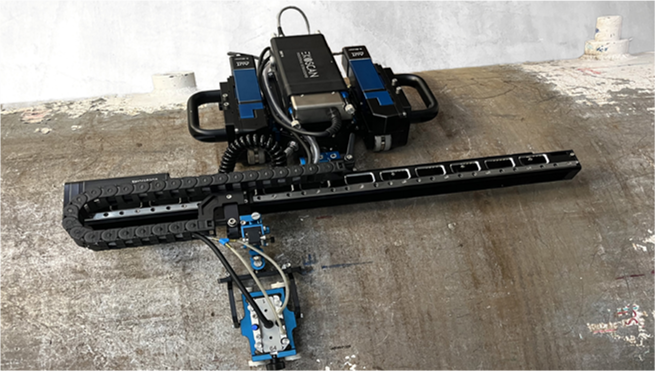

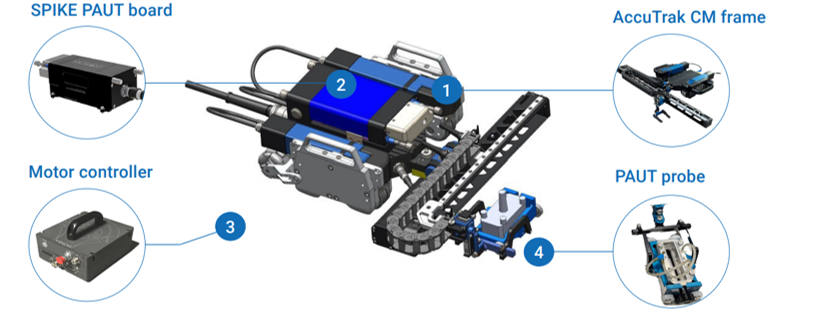

An advanced ultrasonic crawler equipped with phased array technology offers a highly efficient solution for corrosion mapping and thickness inspection in hard-to-access or elevated industrial assets. By integrating the phased array electronics directly onto the crawler, the system minimizes the reliance on long cables, significantly reducing signal degradation and electromagnetic noise. The reduced umbilical—typically carrying only power and digital communication—improves mobility, reduces drag, and simplifies deployment on vertical or curved surfaces. Phased array capabilities enable high-resolution, wide-area scanning with fewer probe passes, increasing productivity while maintaining excellent defect detectability.

This combination ensures safer, faster, and more accurate inspections, especially in environments where scaffolding or manual access would otherwise be time-consuming or hazardous.

- Integrated turn-key solution

- Easy field deployment

- Minimized training time

- Unparalleled inspection reliability

- Reduced operating time

- Streamlined reporting

- High resolution, encoded and traceable data collected

See our other case studies