Rail inspection

Industrial context

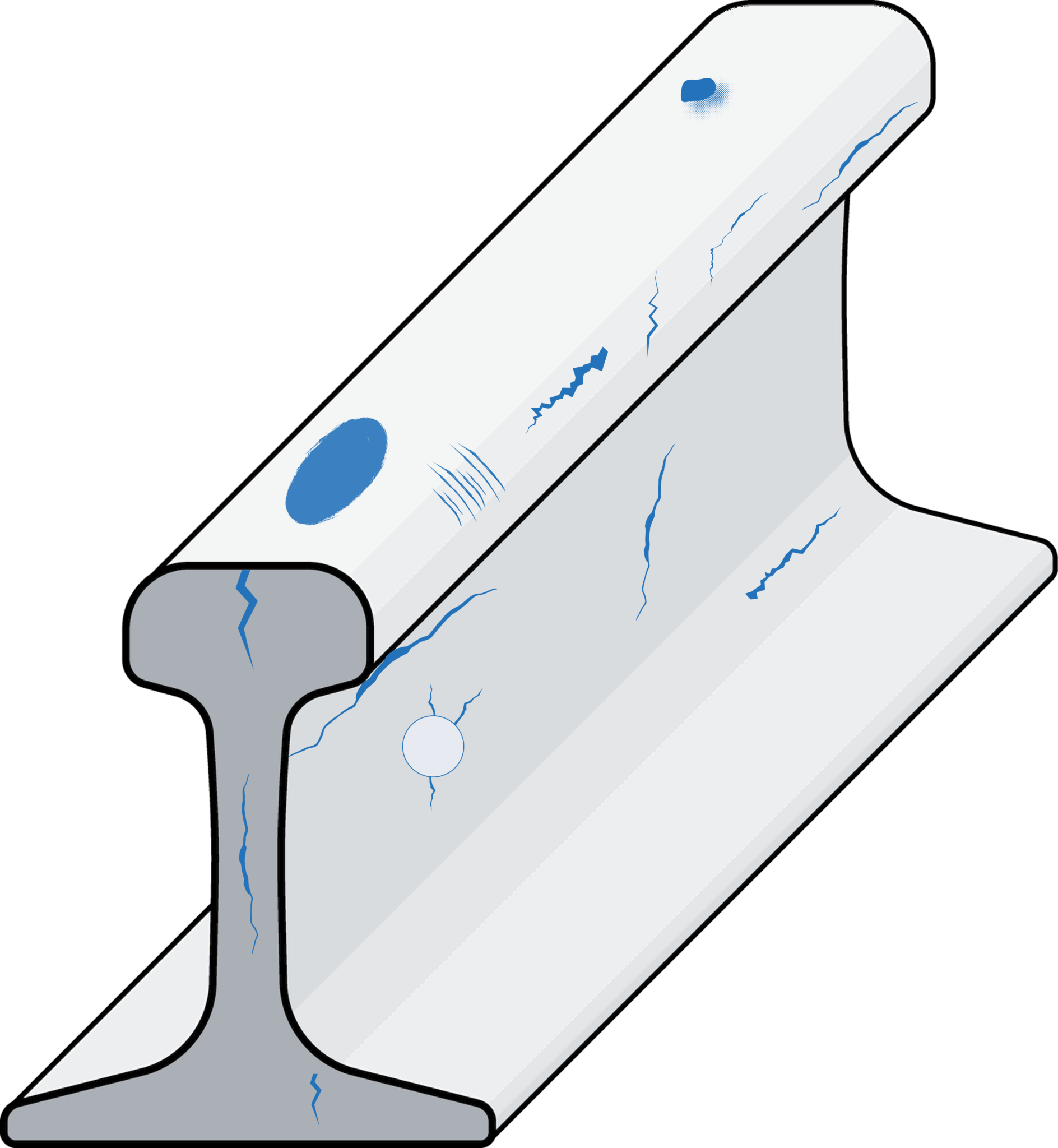

EKOSCAN delivers innovative NDT solutions tailored to the rail industry, enhancing safety and asset reliability. With rail networks facing a growing need to monitor track conditions and optimize maintenance strategies, EKOSCAN’s technologies support the inspection of rails, wheels, axles, bogies, couplers, braking systems, and other structural elements. To meet these demands, the company provides probes, walking sticks, inspection trolleys, and shaft inspection systems designed for accurate flaw detection and comprehensive structural evaluation.

Access to rail lines can be restricted, and traditional rail inspection systems are often heavy, slow to deploy, or require highly skilled personnel. Manual solutions can lack repeatability, while trolley-based solutions may not be robust enough to handle variable field conditions. Software usability is also critical: overly complex systems can lead to inefficiencies and data inconsistency across operators.

1121 / 2121

3014

1122 / 2122

1110 / 2110

1222 / 2222

1223 / 2223

1270/ 227/0

1130 / 2310

1330 / 2330

1530 / 2530

1350 / 2350

1321 / 2321

1360 / 2360

1322 / 2322

EKORAIL combines two complementary inspection platforms: the EKORAIL3 walking stick and the EKORAIL4 trolley. The walking stick weighs under 5 kg and features three custom ultrasonic testing (UT) probes for rapid deployment and ergonomic use. The trolley integrates 20 UT probes and a braking system for stability on extended inspections. Both systems are embedded with SPIKE electronics and operate under a unified software platform that supports assisted calibration, data acquisition, and analysis—ensuring reliability and ease of use regardless of operator background

EKORAIL combines two complementary inspection platforms: the EKORAIL3 walking stick and the EKORAIL4 trolley. The walking stick weighs under 5 kg and features three custom ultrasonic testing (UT) probes for rapid deployment and ergonomic use. The trolley integrates 20 UT probes and a braking system for stability on extended inspections. Both systems are embedded with SPIKE electronics and operate under a unified software platform that supports assisted calibration, data acquisition, and analysis—ensuring reliability and ease of use regardless of operator background

- Full compliance with RATP and SNCF standards

- Lightweight and ergonomic design improves safety and mobility

- Patented electronics for high-speed inspection available on car rail and trolley

- Turn-key deployment with unified software platform

- 100% detection of known defect nomenclature

- Expert-free operation with automated diagnostics and reporting* High resolution, encoded and traceable data collected