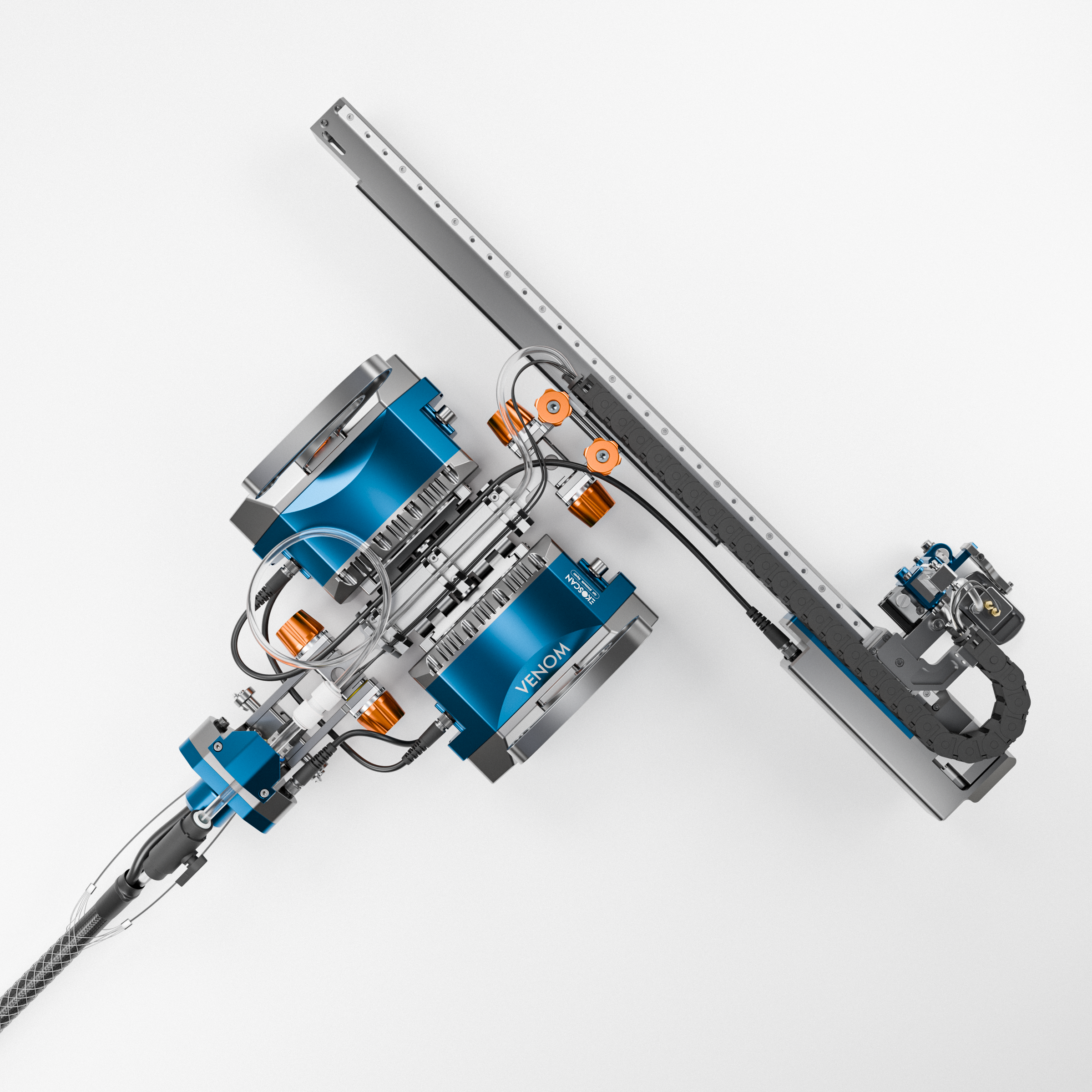

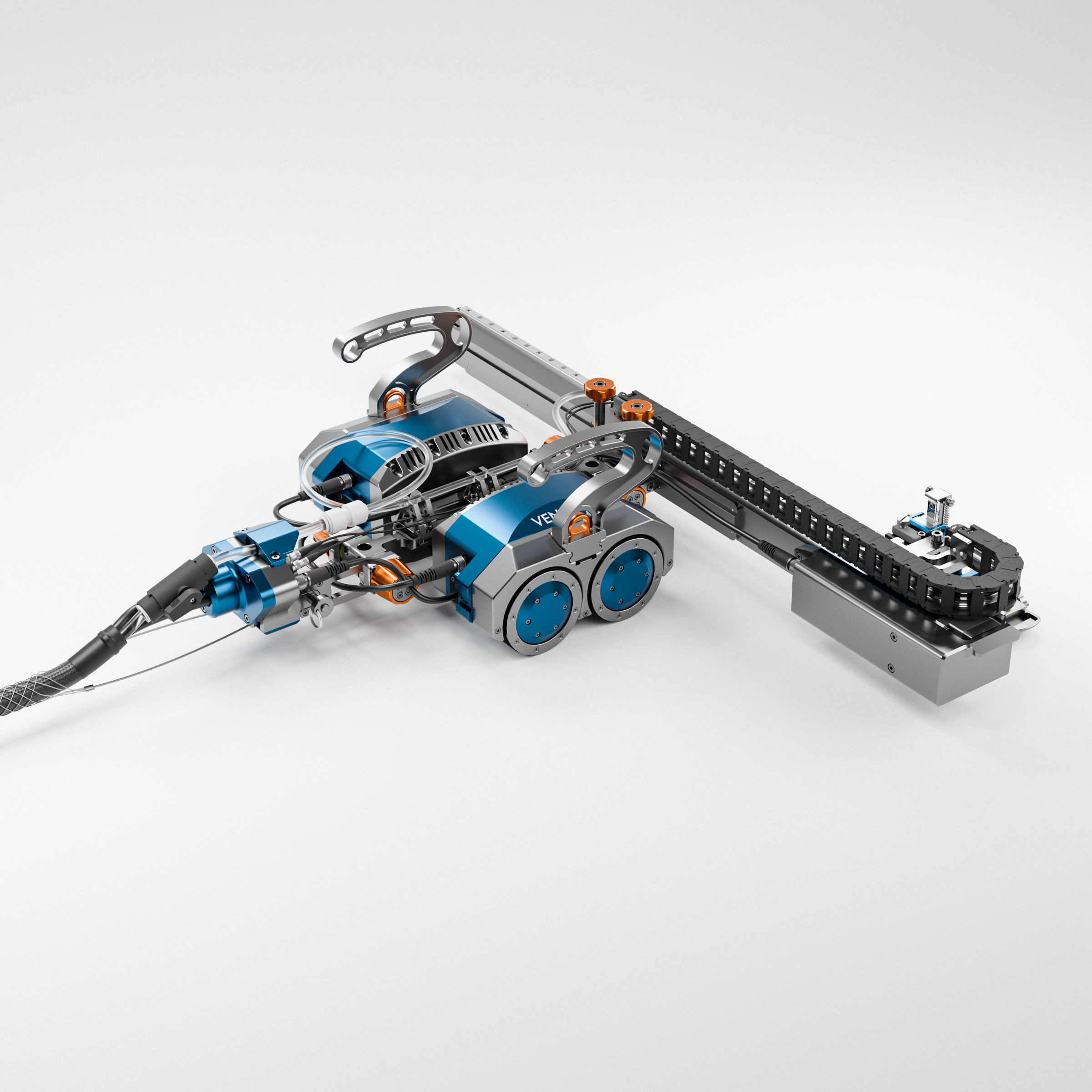

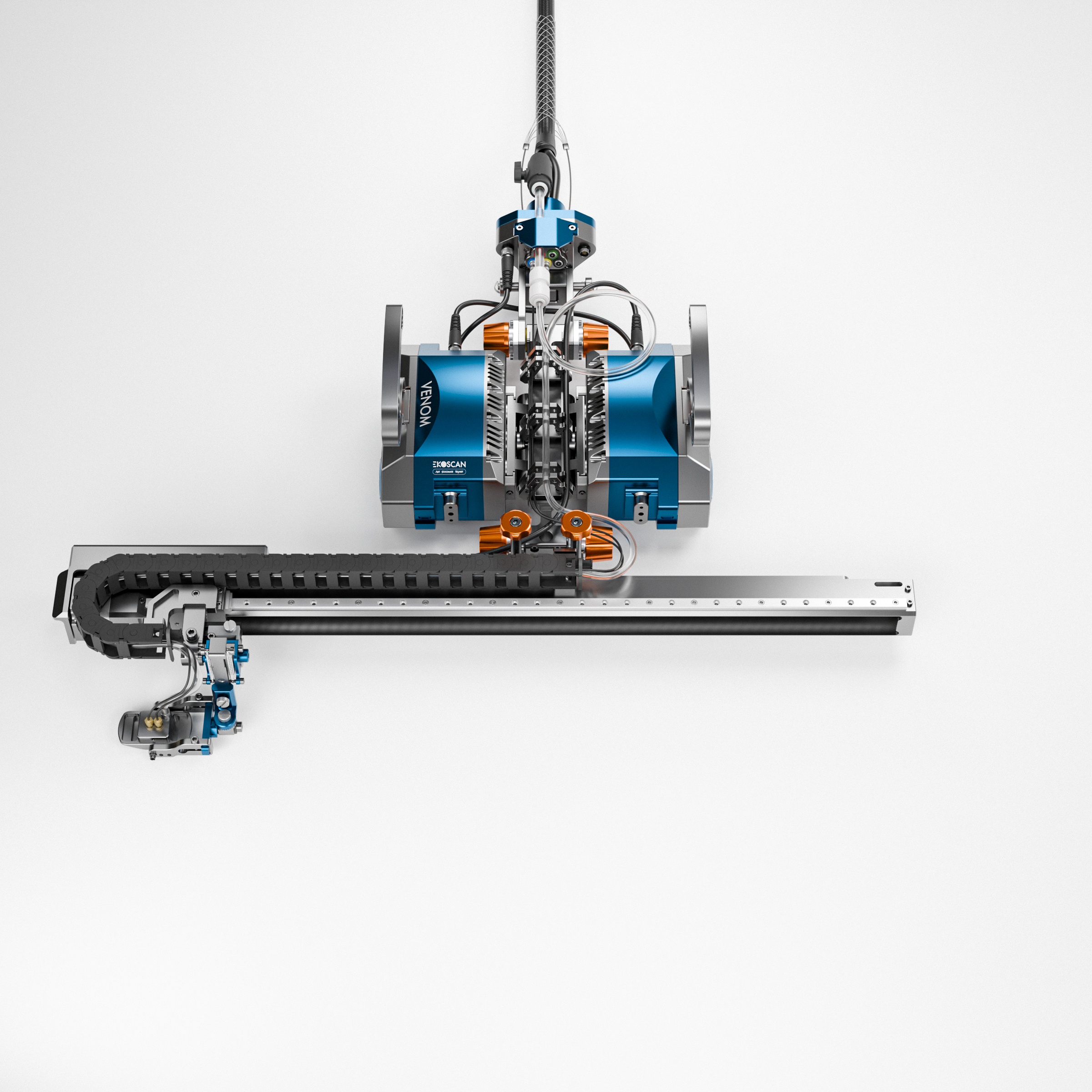

Description

Customer Benefits

Instant return over investment

With remote operation from the ground, VENOM eliminates the need for rope access and scaffolding, significantly reducing inspection time and cost. VENOM is compatible with a wide range of standard NDT devices and does not rely on proprietary flaw detectors, ensuring flexibility with existing equipment. Its intuitive graphical user interface for crawler control allows operators to get started quickly with minimal training.

Rugged for field use

Built tough to handle demanding conditions and repeated use, VENOM builds on over a decade of proven field performance to meet the needs of future applications. Leveraging the legacy of ACCUTRAK, the group’s flagship motorized crawler, VENOM advances inspection capability with greater payload capacity, adaptability, and reliability for the most challenging environments.

Compatible with traceability requirements of most standards

With precise encoding compatible with most flaw detectors (LEMO 16 connector), VENOM provides accurate mapping coordinates to NDT data, ensuring reliable correlation between inspection results and physical locations. This enhances traceability, improves reporting accuracy, and streamlines post-inspection analysis.

Increased job productivity

Designed for easy maintenance with readily available spare parts, VENOM ensures uninterrupted NDT operations and minimizes downtime.

Easy to deploy

With its quick, adjustable, toolless design, VENOM is an intuitive, single-operator scanner that can be set up effortlessly.