Description

Customer Benefits

Comprehensive Inspection Coverage

EMMA integrates multiple electromagnetic methods, including eddy current, eddy current array, RFT, NFT, and MFL, enabling a single software platform to handle diverse inspection scenarios. This ensures full coverage of both surface and sub-surface defects, reducing the need for multiple tools and streamlining inspection workflows.

Operational Efficiency and Productivity

Semi-automated and fully automated scanning, along with encoder-supported C-scan data acquisition, ensures repeatable probe positioning and rapid coverage of large or complex geometries. This reduces inspection time, minimizes human error, and enables more inspections per shift.

Compliance and Safety Assurance

EMMA provides full reporting capabilities and customizable documentation aligned with industry standards, supporting regulatory compliance, traceability, and audit-ready records for critical assets.

Sustainable and Cost-Effective Inspections

By eliminating consumables required in traditional methods such as MPI and LPI, EMMA offers a greener inspection alternative while reducing operating costs and environmental impact.

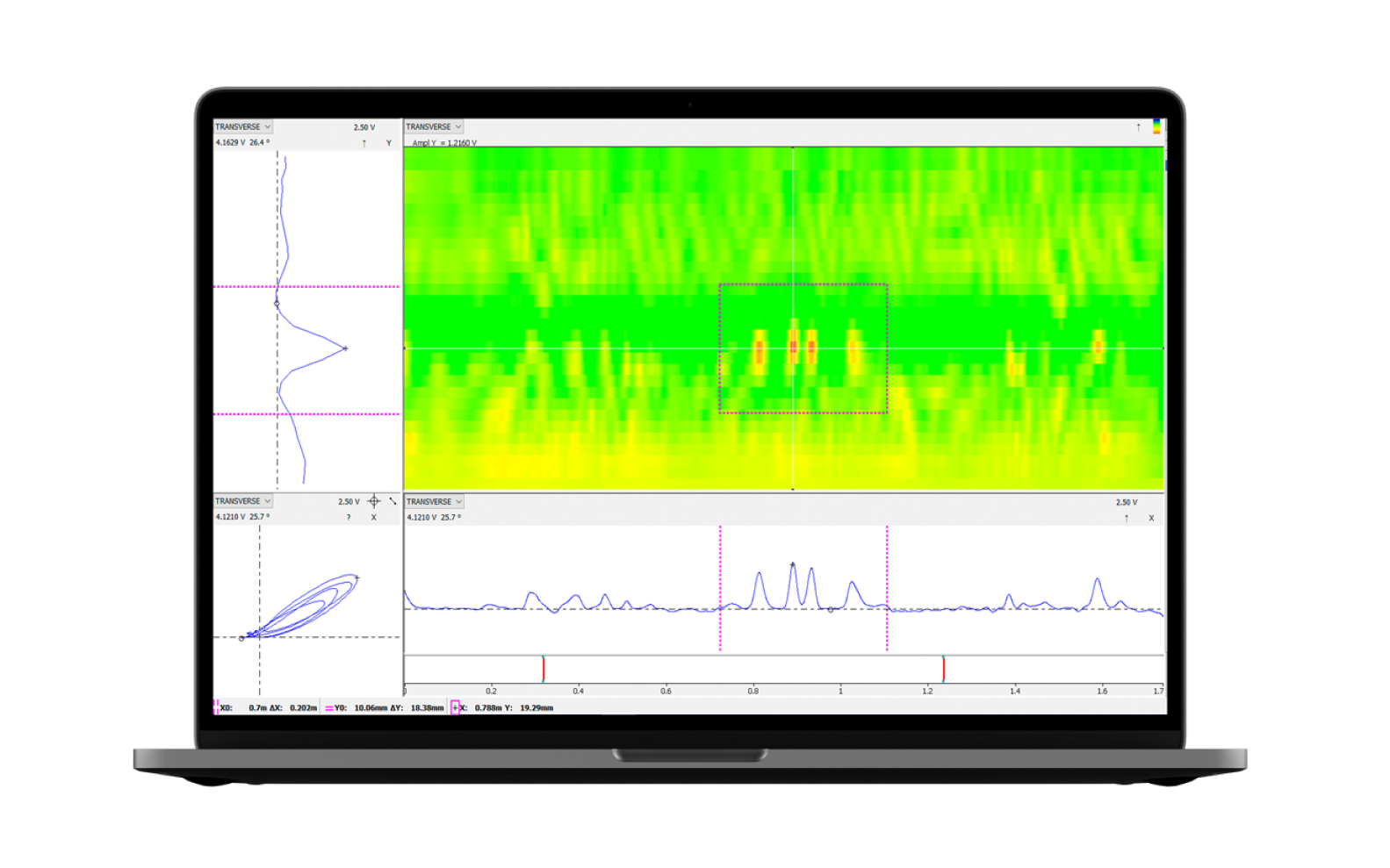

Enhanced Data Quality and Interpretation

Advanced visualization tools, including 3D data views, Lissajous displays, and depth curves, combined with pitch-catch and array-based scanning strategies, improve defect characterization and reduce interpretation ambiguity. Inspectors can make faster, more confident decisions based on high-quality, traceable data.