LEMANS

Custom Ultrasonic Inspection Scanner for Composite Spoilers

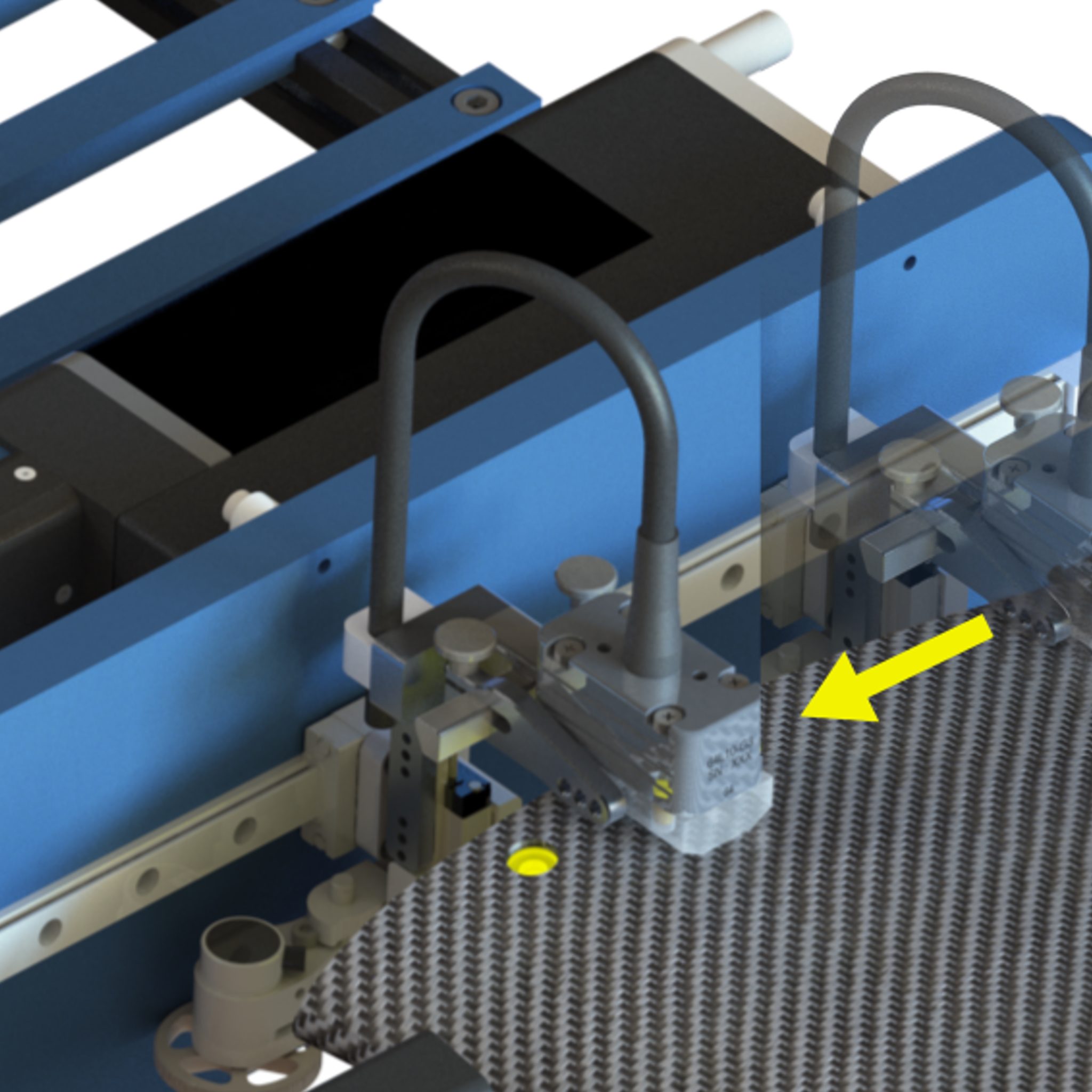

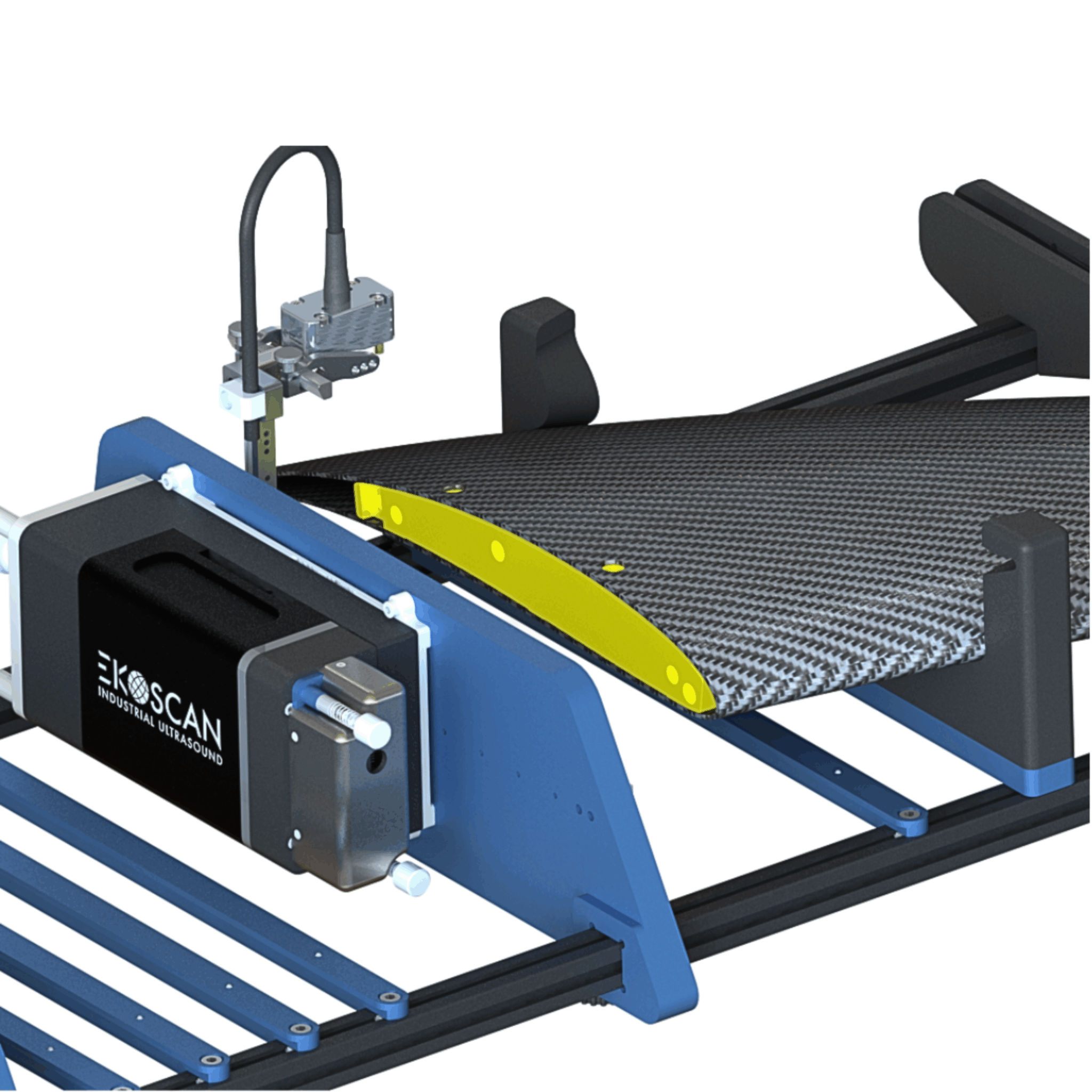

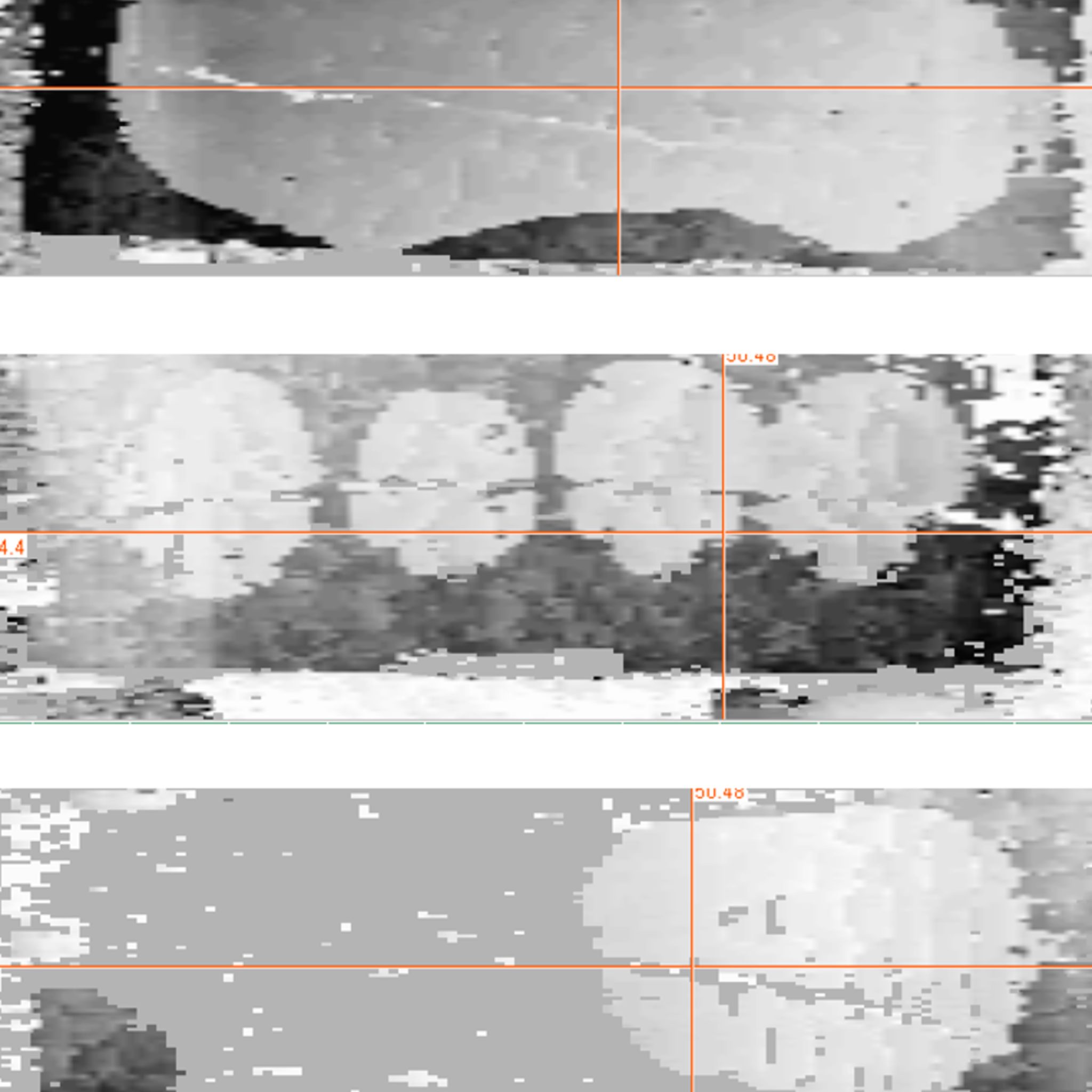

A tailor-made phased-array ultrasonic scanner designed for one-motion operation, paired with a simplified GUI for real-time bond quality diagnostics.

The system guides operators step by step—from part handling and positioning to instant defect detection—eliminating the need for NDT expertise while ensuring racing-grade precision and safety.

- Context

- Pain-point

- Gains

- In the car racing industry, every detail must be perfected—spoilers are no exception. These components are crafted from advanced composite materials with metallic inserts, where the adhesion between the insert and composite is critical to enduring high-stress loads.

- Mechanical engineers and technicians are top-tier professionals, but they often lack expertise in non-destructive testing (NDT)—and they don’t have time to learn it. Yet the bond quality between the insert and composite remains critical. The need for speed comes along the need for safety, ie make sure the parts are made with out defects

- All-level operators can use the system

- Instant result

- Streamlined on the assembly line

- No stopping for third-party inspections

- Operational agility