METIS

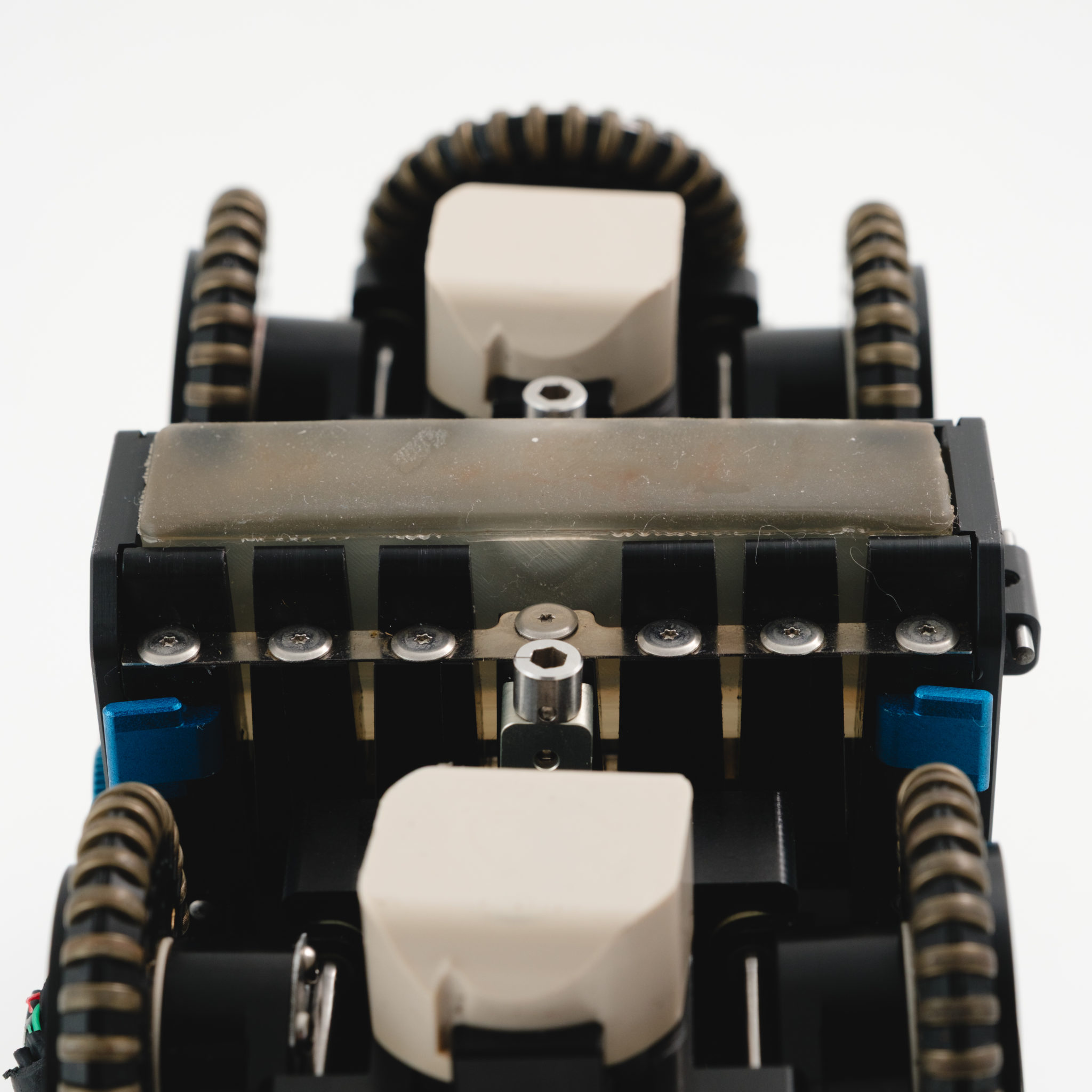

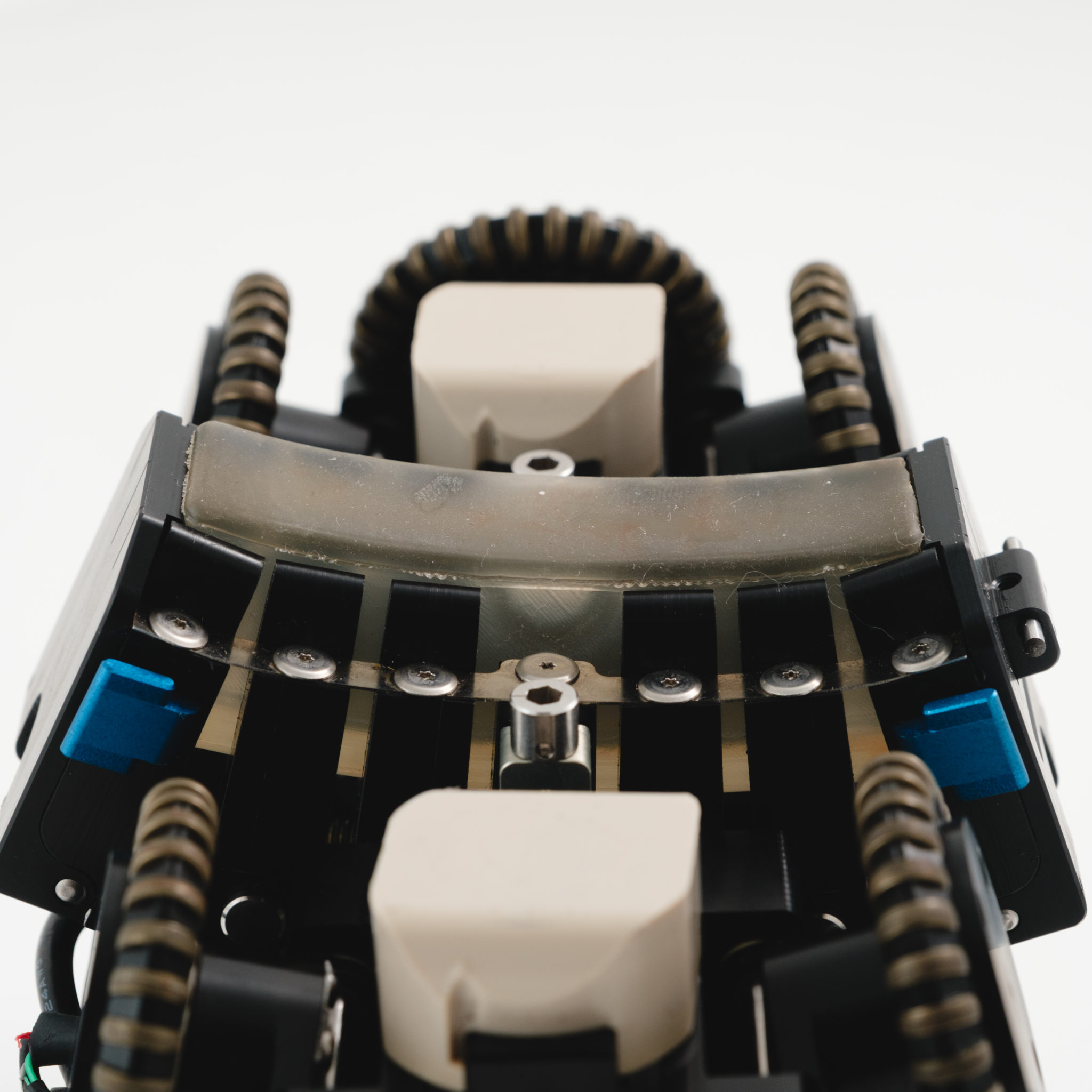

Field-deployable inspection buggy for thickness measurement and corrosion mapping, integrating:

- A flexible phased-array probe for complex geometries

- Dual-axis encoded acquisition for spatial precision

- Real-time analysis and digital recording

- An intuitive, guided workflow operable all-level operators

- Context

- Pain-point

- Gains

- In nuclear facilities, wall thickness measurement is crucial for structural integrity assessments, regulatory compliance, and long-term operation (LTO). Historically, these measurements rely on manual ultrasonic testing and handwritten transcriptions, making them prone to human error, inconsistent data, and limited traceability. As nuclear infrastructure ages, high-fidelity, repeatable, and auditable inspection becomes increasingly critical to safety and asset longevity.

- Lack of traceability and repeatability in conventional ultrasonic inspections

- Operator dependency and risk of transcription errors

- Complex geometries difficult to inspect with standard probes

- Need for predictive maintenance data and audit-ready records

- Safety risks due to ergonomics, chemical couplants, and high manpower demands

- Inspection throughput increased; inspections densified per campaign

- Setup and acquisition time reduced; fewer specialist operators needed

- Inspection repeatability enables reliable LTO decisions Minimizes use of consumables and hazardous couplants

- High ROI via aftermarket accessories and consumables

- Interoperability with legacy systems preserves past investments