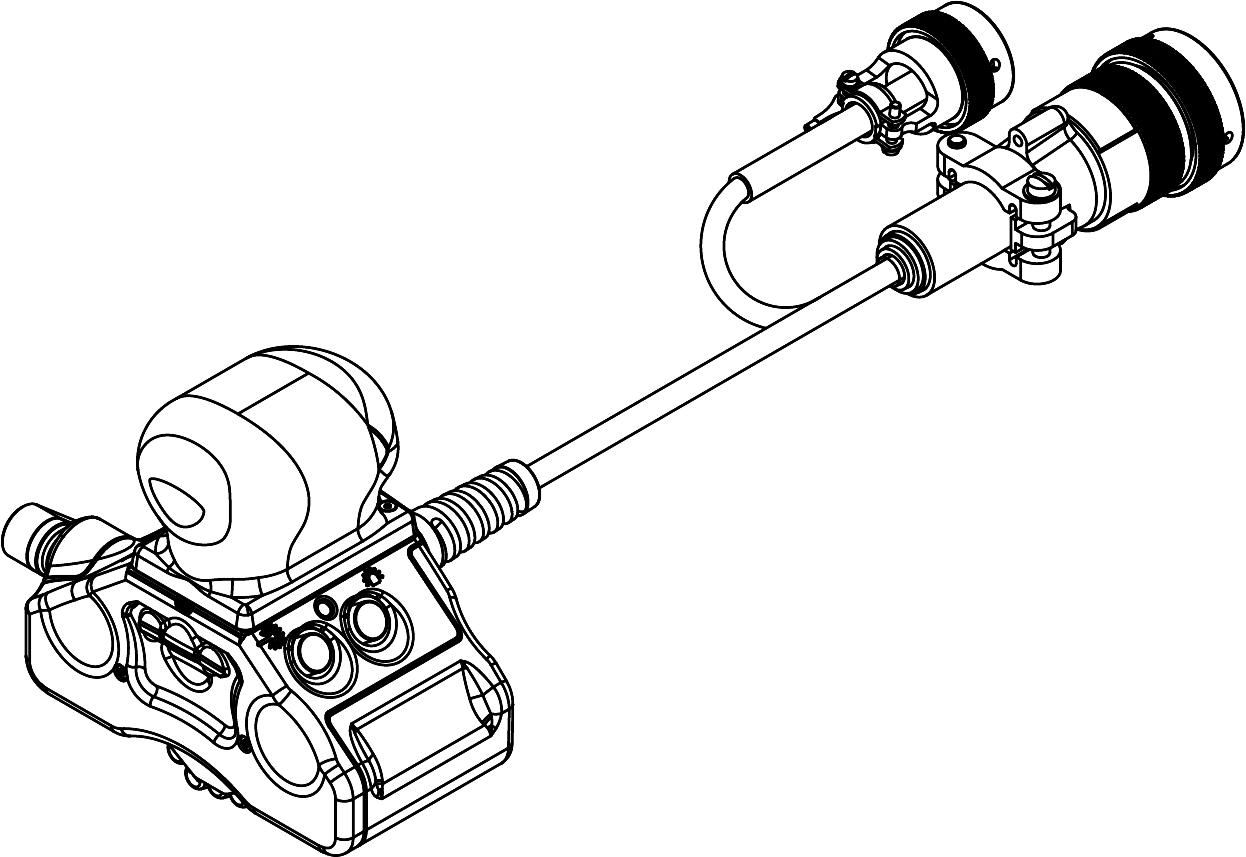

WAVE-180

Specially designed to perform handheld inspections of carbon steel and stainless-steel butt welds that have a rough surface finish.

The probe is equipped with dynamic lift-off technology, which makes it ideal for inspecting painted welds without having to remove the paint. The probe’s memory stores calibration data, making it easy to use and access when needed.

- Features

- Includes

- Options

- Applications

- Weld TypesButt Welds

- TechnologyPCB Coils

- Frequency Range50kHz Fixed

- Coil OD3.5mm

- Coil Quantity2-Rows of 8 (16 total)

- Probe Coverage56mm

- TopologyTangential Coils

- Channels16 Depth Channels 16 / 16 Length Channels - (32 total)

- Resolution3.75mm

- Typical detectable defectSurface breaking crack

- Cable Length3m Standard

- Maximum Lift-Off4mm

- Encoder40 counts/mm

- Probe with integrated cable and encoder.

- Supplied in a rugged transport case.

- 5m cable

- 10m cable

- Carbon steel butt weld inspection at manufacture or in-service.

- No need for coating removal as this probe has automatic lift-off compensation.